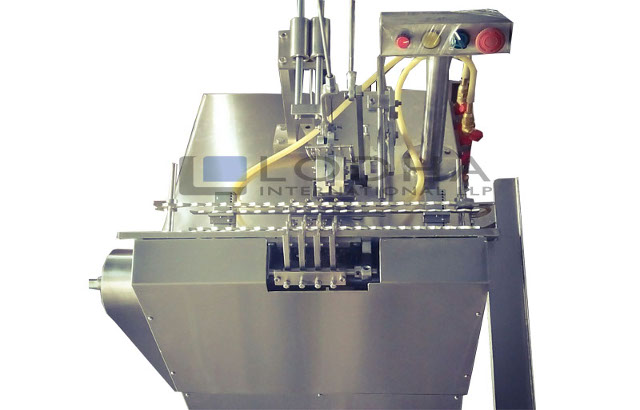

Ampoule Sealing Machine Model: LI-AS s used for sealing of glass ampoules. Machine is widely uses in pharmaceutical, biotech, cosmetic, veterinary & chemical industry. We design Ampoule Sealer Machine as per our standard model as well as custom made models according to customer’s specific requirements. Machine built on principal of slant travel of ampoules while sealing to take care wide variation of ampoule neck dimensions, thicknesses and ovality of available ampoules.

Ampoule Sealing Machine is built on Stainless Steel square pipes frame & totally encompassed with Stainless Steel coverings in pleasing matt finish design. Large opening area configured on bottom side of the machine for absolute cleaning and maintenance of the machine. The pendant type electrical control panel is lifted from machine for ease of operation and safety.

Salient Features:

- Compact GMP model.

- Production output ranging from 30 ampoules/minute to 150 ampoules/minute.

- All contact parts made from AISI SS 316L & other Non-contact parts made from AISI SS 304.

- Machine is suitable to fill 1ml to 20ml ampoules and minimum change over parts from 1ml to 20ml ampoule size.

- "No Ampoule - No Filling" system.

- Ampoule neck centering during gas flushing and filling operations.

- Possibility of nitrogen gas flushing before, during and after filling.

- Full accessibility allows easy maintenance.

- Machine equipped with pre-warming station.

- Minimum change over time, little maintenance & easy cleaning.

Process Operation:

The sterilized ampoule tray directly loaded in to slant hopper of the unit. The Synchronized star wheel delivers ampoules one by one on moving eccentric ampoule rack in single/two/four/six. During the stoppage of rack sequentially pre-gassing, filling, post gassing, pre-heating and final sealing is achieved. Duly filled sealed ampoules then collected on collection tray automatically without hand touch.

The machine performs the following operations:

- Ampoule feeding by in-feed hopper, star wheel and ampoules transfer into transport rack.

- Two ampoules advanced per machine stroke.

- Centering of ampoules necks during pre-heating, post heating, gas flushing and liquid filling.

- Rotation of ampoules neck in the pre- heating and heating station.

- Elimination of burdened-off ampoule tips by clippers and ejection into a separate container.