Ampoule Filling Machine

A pharmaceutical ampoule is a modern automatic machine which has been designed specifically to increase the rate of production in the pharmaceutical industry. This ampoule filling and sealing machine is specifically for the filling drugs into the glass ampoules. If you’re in the business of packing liquid drugs, then most definitely, you need an Ampoule Filling Machine. It provides an effective way of filling and sealing ampoules. More importantly, going for an automatic ampoule filling and sealing machine will bring increased productivity, efficiency, and accuracy in the packaging process.

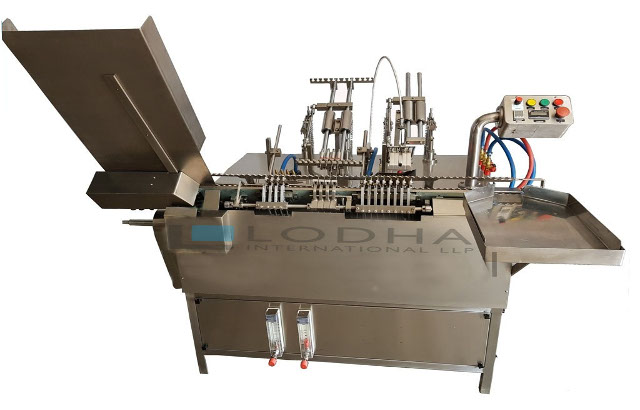

LODHA is proud to present its latest model LI – AFS models for ampoule filling. The machine is not only the best fit for pharmaceutical industry but also a preferred choice for biotech, cosmetic, veterinary & chemical industry. The Machine is built on Stainless Steel square pipes frame & totally encompassed with Stainless Steel coverings in pleasing matt finish design. The advantages to use LODHA LI-AFS machine of ampoule fillings are as follows:

Some of the main advantages of ampoule filling machine include:

- Ampoules protect the drugs from environmental dust and microorganisms.

- Makes it easy to handle and store the drugs at the right content and amount to be used in hospitals.

- Full accessibility of the machine allows for easy maintenance of the machine

- It has a faster changeover of ampoules since the process of production is very fast

- It has a higher output of up to about 150 ampoules per minute

- It has flow meters which ensures that the flames are regulated easily

Ampoule Sealing Machine

LODHA LI-AFS machines are known for its smooth operations. The infeed conveyor receives the ampoules from the sterilizing tunnel. Later the ampoules are loaded into the conveyor belt into a screw conveyor in the upright position. What happens again is that the screw conveyor then transports the ampoules to the segment wheel to be carried to a conveyor cradle. It is worth noting that the conveyor cradle carries 8, 6 or 4 ampoules in a group through various stations. LODHA’s Ampoule Sealing Machine also perform pre-gassing, before filling, filling, post-gassing after filling, pre-heating, heating which is done in vertical positions.

The machine performs the following operations:

- Ampoule feeding by in-feed hopper, star wheel and ampoules transfer into transport rack.

- Two ampoules advanced per machine stroke.

- Centering of ampoules necks during pre-heating, post heating, gas flushing and liquid filling.

- Rotation of ampoules neck in the pre- heating and heating station.

- Elimination of burdened-off ampoule tips by clippers and ejection into a separate container.